What is Stock Control?

Every business needs to keep track of the items that it manufactures or sells (the stock). The system that monitors the items in stock is called the stock control system.

E.g. in a store, the stock includes all of the items on the shelves and out the back in the storeroom.

It is important that a business does not keep too much stock, nor too little.

E.g. in a store, the stock includes all of the items on the shelves and out the back in the storeroom.

It is important that a business does not keep too much stock, nor too little.

- Too much stock costs money as you have to store it all somewhere

- Too much perishable stock (e.g. food) means that it may go bad before it is sold

- Too little stock means that you might run out of stock before the next delivery arrives

Data in a Stock Control System

A stock control system is basically a database.

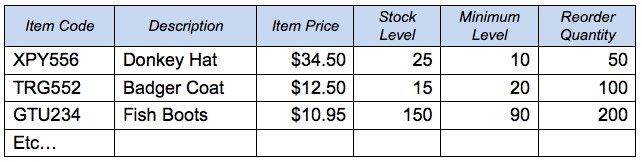

Each record (row) of the database is identified by an item code (the primary key).

Other fields in each record would include:

Each record (row) of the database is identified by an item code (the primary key).

Other fields in each record would include:

- Description

- Item price

- Stock level (the number of items held in stock)

- Minimum stock level (when stock falls below this, it needs to be reordered)

- Reorder quantity (how many items we should order each time)

Receiving New Stock

When items are added in to stock (because a delivery has arrived) this is recorded in the stock control system.

The code of the new items is input to the system (usually using a barcode scanner, or similar technology). The record for the item is found in the stock database, or a new record is created, and the stock level is increased.

The code of the new items is input to the system (usually using a barcode scanner, or similar technology). The record for the item is found in the stock database, or a new record is created, and the stock level is increased.

In many stores, the POS system is directly linked to the stock control system, so that stock levels are adjusted as soon as an item is sold.

Selling / Delivering Stock

When items are taken from stock (because they have been sold, or delivered somewhere) this is recorded in the stock control system.

The code of the item is being sold/delivered is input to the system (usually using a barcode scanner, or similar technology). The record for the item is found in the stock database, and the stock level is decreased.

The code of the item is being sold/delivered is input to the system (usually using a barcode scanner, or similar technology). The record for the item is found in the stock database, and the stock level is decreased.

In many stores, the POS system is directly linked to the stock control system, so that stock levels are adjusted as soon as an item is sold.

Automatic Re-Ordering of Stock

Stock control systems make it very easy for stock levels to be monitored, and for stock to be reordered when it is running low.

The stock control system regularly goes through all the records in the stock database and checks if the stock level is less than the minimum stock level.

The stock control system regularly goes through all the records in the stock database and checks if the stock level is less than the minimum stock level.

Is Stock Level < Minimum Stock Level ?

If the stock is too low, it is reordered from the supplier. The quantity that is ordered is read from the stock database (larger amounts for more popular items)